Tension & Extension Overview

S R Spring warehouses the largest inventory of high-grade extension springs in the world. Extension springs are designed to absorb and store energy as well as create a resistance to a pulling force. It is initial tension that determines how tightly together an extension spring is coiled. This initial tension can be manipulated to achieve the load requirements of your particular application. All S R extension springs are wound with an initial tension force which offers a small deflection load for secure installation “holding”. The initial tension is equal to the minimum force required to separate adjacent coils. Each spring is of the constant diameter type with a variety of hook/loop styles.

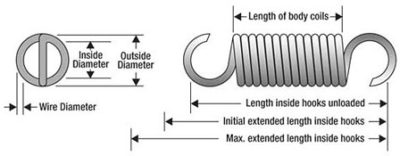

Dimensions Measurement Guide

- Hold the spring in one hand, and the verniercalipers in the other hand.

- Place thevernier calipers across the outside coil, either at the end or the center of the spring. This is called the Outside Diameter (O.D.).

- Place the verniercalipers on the wire at one end of the body coil of the spring. This is called the Wire or Material Size.

- Place the verniercalipers (or tape measure) on the full length of the spring, inside the hooks. This is called the Length (L.I.H.). (see diagram for example)

Application

Automobiles, Textile loom & machinery, Agriculture pumps, Relays, Rotary switch, , Balance Scale, Toys, Garage Doors, Washing Machine, Refrigerator, Electronic, Electrical & switchgear products and various types of spring tensioning device.